3D product visualization and made to order, a strategy for success?

Table of content

The custom made production is aimed at the satisfaction of each customer by proposing a unique offer and, at the same time, it is industrially produced at a competitive cost.

Initially exclusively handcrafted and dedicated to luxury and high-end products, custom manufacturing is now used by a wide range of customers and products, thanks to recent industrial advances.

Mass customization and the smart industry are now accelerating this trend.

Exploring the Benefits of Made to Order or Print on Demand Production

3D visualization for custom products

Using a 3D product configurator allows customers to customize their products according to their preferences, resulting in a unique, personalized experience that meets their specific needs. Viewing a product in a 3D visualization allows you to visualize a product that doesn't fully exist until the manufacturing process is complete, incorporating the customer's unique choices.

The latest trends in made to order manufacturing are revolutionizing industries by offering customized products and experiences that meet individual needs and preferences.

Using a 3D configurator solution for manufacturers creates a seamless experience that bridges the gap between manufacturing and customer expectations.

Print on demand: the rising concept of ecommerce

Print on Demand (POD) is a new concept that enables artists or entrepreneurs to effortlessly sell customizable products in e-commerce. There is no need to stock products or manage infrastructure, and no investment is required. Products are manufactured only when an order is placed and delivered directly to customers by a specialized platform. All it takes is a simple e-commerce website and a concept to easily and risk-free sell products.

Various industries and brands now provide customizable 3D products

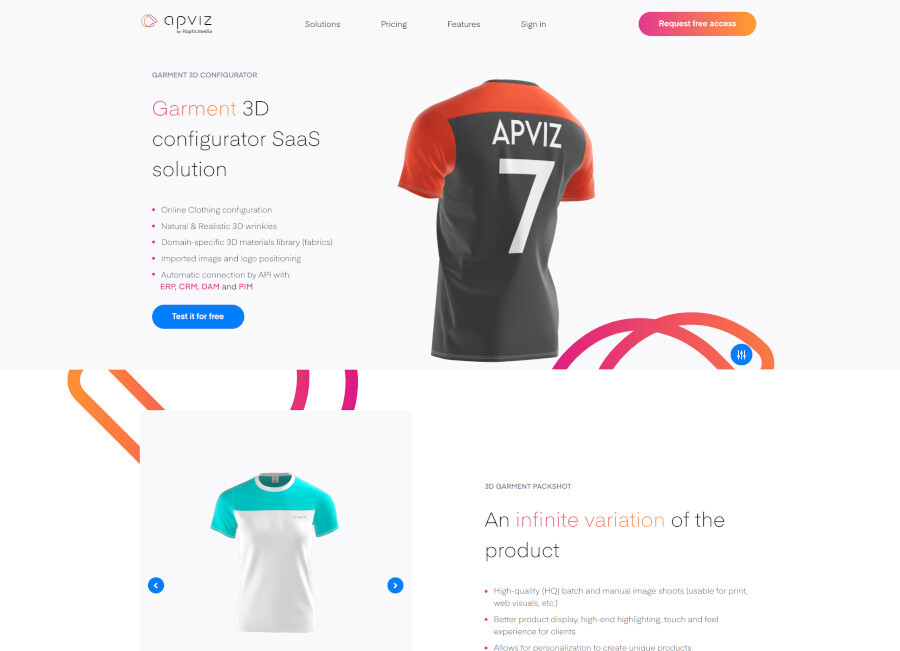

3D visualization for fashion and apparel

Many clothing brands provide a custom made service that enables customers to customize their apparel. Customers can select fabrics, colors, shapes, and add unique designs and text to make the clothing more personal.

Historically, tailors and garment makers provided made-to-measure clothing, but also offered handcrafted one-of-a-kind pieces for their customers.

Tailored suits or bespoke shoes were the norm, but with industrialization, mass-produced manufacturers offered clothing in a limited number of sizes and colors for everyone. This reduced manufacturing costs and lowered prices by making standardized products available to everyone.

But it also made brands and retailers handle big inventories. This caused some problems, like moving production to cut manufacturing expenses, and facing high costs for storing and selling unsold goods.

Thanks to mass customization, more and more brands are implementing innovative customization strategies. By using the fashion 3D configurator, brands can give customers an engaging experience on their e-commerce sites.

Brands such as Lacoste, Nike, Adidas, North face, Under Armour already use a 3D configurator solution to offer a customized product on order.

More information on the Apviz 3D apparel configurator solution

Furniture configurator

Custom furniture is popular among a broad customer base seeking one-of-a-kind pieces that cater to their unique preferences and requirements. This option empowers customers to carefully choose the size and hues of materials that align with their vision. Plus, by examining their custom furniture in 3D from the comfort of their home using augmented reality, customers can gain a precise representation of how the furniture will look in their home.

When the furniture is made to order by an agile factory. This allows to reduce considerably the return costs when it is sold in ecommerce.

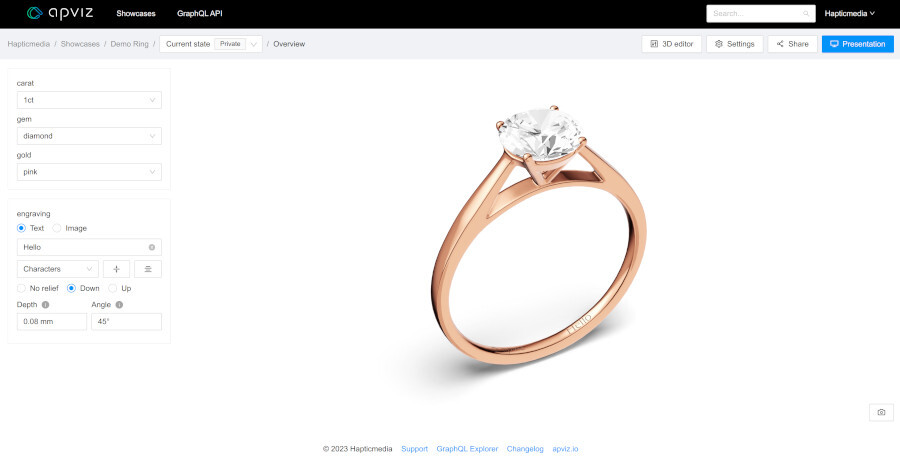

3D configurator for custom made Jewelry

Some jewelry makers provide customizable services that enable customers to create bespoke jewelry that reflects their individual style. A 3D jewelry configurator facilitates a realistic visualization of what the jewelry will look like. For instance, in a particular design, the correlation between carat size and ring size can be noticeably distinctive. The appearance of a ring with a size 45 featuring a 2-carat diamond contrasted with a ring of size 52 featuring a 0.2-carat diamond appears strikingly different. Engraving a personalized message is a great way to make a unique piece, but it's hard to anticipate the end result. A real-time 3D jewelry configurator for e-commerce, like Apviz.io, can help customers see exactly what they're getting.

3D configurators show customers a realistic and interactive visual representation of the 3D jewelry design, giving them a better understanding of what they're buying and helping them feel more confident in their purchase decision.

More information on the Apviz 3D jewelry configurator solution

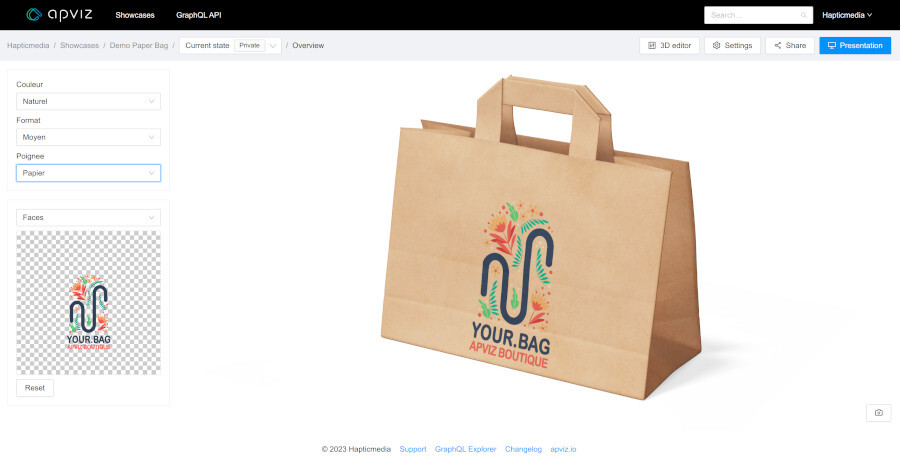

3D visualization for print on demand

In the same vein as made to order, print on demand allows you to personalize a packaging design directly on your printer's website. For instance, you can create your packaging online by selecting from a range of box shapes. Then, you can choose your colors, import your logo, customize your text, and even simulate effects like embossing. Online packaging 3D configurator on the website enables you to visualize and validate your packaging design before it's made. Once you've made your selections and determined the quantity, you can place your order. It will be manufactured and delivered directly to your home or business office.

For the printer, this greatly reduces returns and customer dissatisfaction, and ensures that customers have a clear understanding of the final designs and quality of the print effects. This minimizes the risk of misunderstandings and ensures customer satisfaction and loyalty throughout the process.

More information on the Apviz 3D print on-demand configurator solution

Acceleration of new technologies for manufacturing and new trends

New technologies, e-commerce and social media offer today relevant tools that allow brands to better understand their customers' expectations and to develop a customer-centric marketing strategy fully focused on the customer and entirely oriented towards his choices.

The way that we produce today has changed thanks to agile manufacturing, additive manufacturing, print on demand, robot, cobot.

On-demand manufacturing requires a significant transformation

These new opportunities and trends offer many benefits for brands, but they also demand a substantial and deep overhaul in how they approach production and work.

Work and production methods are evolving thanks to current cloud tools and data (CMS, CRM, PIM, DAM) that enable the management and tracking of the product life cycle, from its CAD design to its market release.

A high quality 3D SaaS solution that allows the visualization of 3D digital twins of products allows for the conceptualization of products not as they will be sold, but through the definition of their business rules.

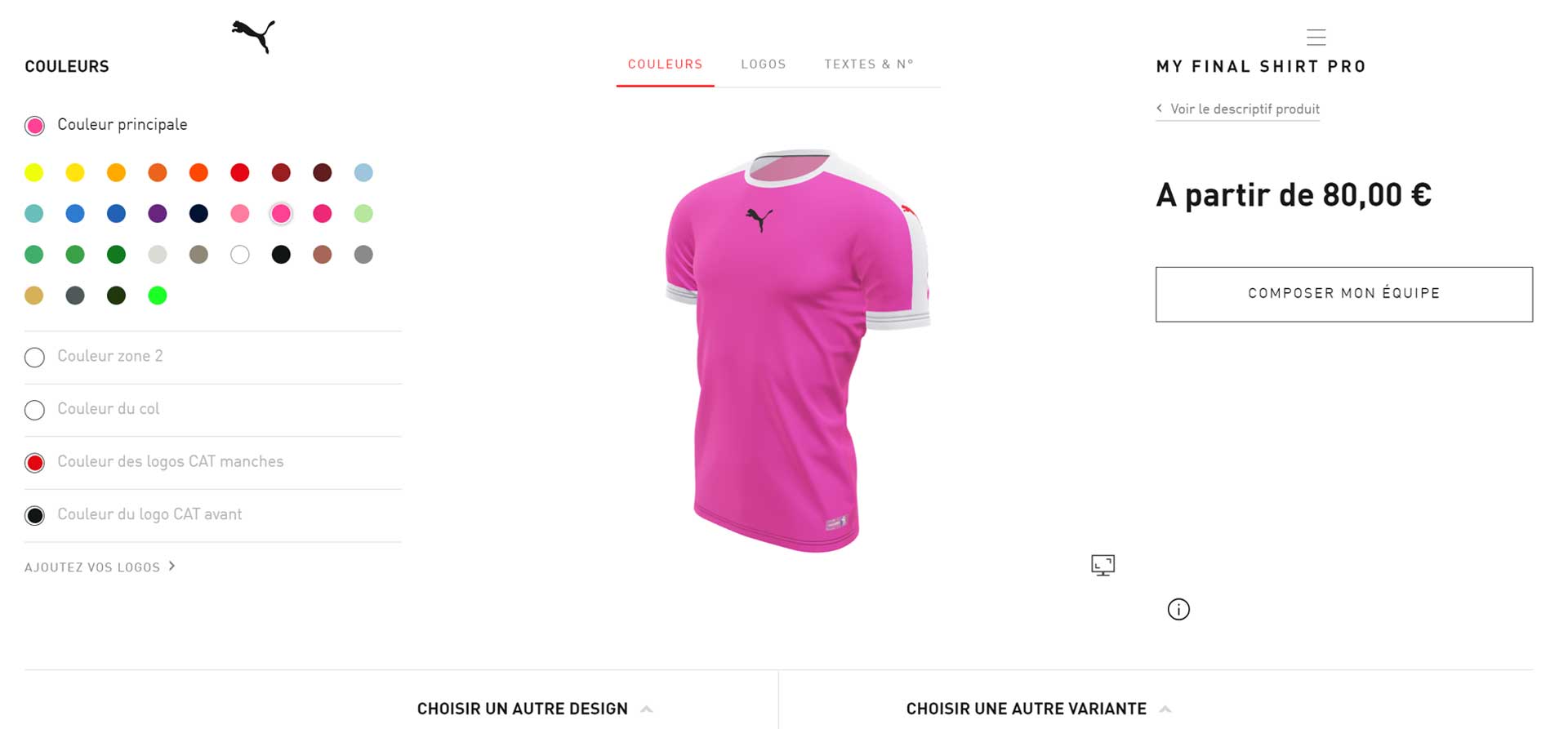

For example, with a custom apparel, let's consider a product is a sport jersey, the following customization options are available:

- Sleeve Options: 18 colors for both long and short sleeves.

- Front Options: 12 colors for the front of the t-shirt.

- Back Options: 12 colors for the back of the t-shirt.

- Collar Options: 5 different collar shapes to choose from.

- Logo Placement: The customer can choose from 4 different locations to position the logo.

- Logo Color: The customer can select the logo color from a range of 12 colors.

- Initials: The customer has the option to add their own initials to the t-shirt.

Please note that customers can customize their jerseys with a wide range of options to suit their preferences.

The product only exists digitally after customization by the customer and physically after the order is placed and manufactured.

A 3D SaaS platform like Apviz provides all the agility and scalability required for the visualization of made to order products on the internet and their connections to their ecosystems.

The "Marking and engraving" module in Apviz takes personalization to the next level by allowing hyper-customization, such as simulating engraving or stamping of texts on the product and importing images that will be printed on-demand using Print on Demand technology.

Business with sustainability

Made to order allows customers to personalize products to their preferences, resulting in higher customer satisfaction and longer product life cycles. By offering durable, customizable items, businesses can reduce the frequency of replacements and contribute to a more sustainable consumption pattern.

Another benefit of made to order is its potential to reduce carbon footprint and storage costs by minimizing delivery distances and adopting agile local production that only manufactures products upon order. This eliminates the need for inventory, and only the products that are sold are produced, resulting in more sustainable practices.

Custom product builders in the US allow for personalized creations. Products ordered in the US are produced in agile factories or printing plants located in the US and delivered locally, minimizing unnecessary, costly, and polluting travel.

Increasing customer satisfaction

By allowing customers to personalize their products according to their preferences and needs, it enhances their overall shopping experience. The ability to customize products to their liking leads to a higher level of customer satisfaction and a stronger connection between the customer and the brand. Additionally, the made to order model ensures that customers receive products tailored specifically to their requirements, resulting in higher customer satisfaction levels compared to mass-produced, one-size-fits-all items.

By offering unique products that are made specifically for each customer and tailored to their exact measurements, it increases customer satisfaction. The user experience plays a crucial role in avoiding disappointments and facilitating the purchasing decision. Having a well-designed and user-friendly configurator is essential to guide customers through the customization process. It should simplify the choices, provide clear options, and minimize the risk of making poor design choices. A thoughtful and intuitive configurator helps customers feel confident in their selections and reduces the likelihood of dissatisfaction or regret.

Image Credit: Mike van Schoonderwalt - Pexels

Seamless Marketing to Manufacturing

Apviz custom product visualizer offers a tool that provides reassurance and helps users make informed decisions by offering pre-validated designs by the brand. It establishes a balance between offering enough freedom for unique, customized designs and totally free choices that could be intimidating. This expertise is made possible through the fully connected 3D visualization software,

Apviz, which seamlessly integrates with other databases through its API. With this solution, brands can offer a seamless and unique journey from the consumer to the manufacturing and delivery of products. You can effortlessly import a wide range of 3D products and establish business rules and customization guidelines enabling efficient lifecycle management for a multitude of products.

Conclusion

The future is undeniably headed towards these new production models, but there are still many barriers that require us to remain vigilant.

The foremost challenge is to always prioritize the added value perceived by your customers as the main guiding principle. Considering the significant changes in production methods and the investment required for the equipment and infrastructure necessary for on-demand production, it is crucial to ensure that the value delivered to customers justifies these transformations.

The focus on delivering additional value to the customer should remain the guiding principle of your made-to-order business. The overall ergonomics of the customer experience offered is also key to the success of your transformation. By prioritizing a seamless and user-friendly experience, you can enhance customer satisfaction and ensure the success of your made to order initiative.

Does your project effectively provide your customers with a high-quality product that offers a unique design yet is easy to configure, delivering a seamless customer experience?

Try Apviz 3D Made to Order solution

Featured image: Helena Lopes - Pexels.

By Hugo Rimélé - Thu Jul 06 2023

Stay informed

Discover more articles

17 e-commerce trends to leverage for higher sales

From augmented reality to omnichannel marketing and remote services, e-commerce trends are adjusting to give customers the best possible experiences....

Cosmetics industry trends and marketing techniques

The cosmetics industry, also known as the beauty industry, includes fragrances, skin, hair and personal care and color cosmetics like facial make up products, nail care products, lip care products, and eye make-up products....

What is 3D Ecommerce?

Discover how major brands are leveraging 3D ecommerce to deliver outstanding shopping experiences. This guide explores WebGL visualization, 3D configurators, AR/VR, benefits such as increased conversions, cost drivers, and the future role of AI in pe...