How the fashion industry can use 3D technologies to put an end to overproduction

Table of content

Globally, fashion is one of the industries that generates the most waste. An essential part of this is played by overproduction, a phenomenon associated with companies’ inability to assess market demand and their desire to reach as many consumers, as possible.

Still, with the global landscape becoming more competitive, profits reducing and governments everywhere drawing attention toward the industry’s need to stop manufacturing more than is necessary, brands need to consider different approaches to operations and business.

This is where 3D tools come in. Due to its many advantages, this technology enables companies to improve demand forecasting, reduce time-to-market, develop no-stock strategies and offer made-to-order products, while also keeping costs down and consumers satisfied.

Read further and discover what trickers overproduction, what are its global consequences and how you can use 3D technologies to optimize your operations.

What you need to know about overproduction

What generates overproduction

The development process for retail brands usually takes 3-6 months, from ideation to sending the product to market. Designing, sampling, merchandising, and producing require teams to collaborate and factories to combine manual work with automated processes.

Companies need to predict what consumers will buy months in advance, which raises several challenges. In the age of social media and influencer relations, trends may come and go in days, even hours, which means that assessing what to produce has multiple variables that make it prone to failure. In this context, brands often create more items that they sell.

image credit : the european environmental bureau

Overproduction is terrible for companies’ bottom lines and the environment

The figures, in this regard, look quite scary from a global perspective. According to a 2017 report issued by the Ellen MacArthur Foundation, over $500 billion is lost yearly due to underused and unrecycled clothes. Moreover, out of around 150 billion garments made yearly, only a maximum of 30% is sold full-priced, up to 50% is discounted, and the rest is often trashed.

In a 2018 report, fast fashion brand H&M stated that the value of its unsold clothes was $4.3 billion, raising even more questions about the industry’s sustainability. They are now trying to tackle it with the H&M Garment Collecting program.

Still, unsold clothes aren’t the only way overproduction accounts for waste. Even the manufacturing process is a generator. Massive losses of resources during production are due to cutting out fabrics which lead to unusable pieces.

Sources show that 35% of all supply chain materials become waste before consumers even get a chance to decide whether they want to buy a specific design. This means that both clothes that sell and those that don’t generate waste, with the second being an even more serious threat to our ecosystems and companies’ bottom lines.

Besides its direct costs, overproduction also generates additional losses for companies that have to pay for warehousing and storing, logistics, and destroying the actual products once they turn out to be unsellable. To compensate for those and keep prices low, many brands, particularly mainstream ones, need to cut costs somewhere. They usually do so by reducing the quality of their items, which, in turn, affects their reputation and generates unsatisfied consumers.

Overproduction also harms the environment, as the unsustainable practice uses natural resources, specifically water, and emits carbon dioxide. Moreover, most clothing landfills pollute natural areas in the Global South, contributing to destroying entire ecosystems.

Fashion’s material of choice, polyester, which has overtaken cotton in usage, according to Bloomberg, is made from petroleum. Big amounts of polyester are inadequate for the planet. Producing it requires energy and generates two times more carbon dioxide than it would for cotton. Moreover, the fabric generates microplastics with every wash, thus polluting water and land.

How 3D technologies help companies tackle overproduction

The solution to all the above comes from technology. Incorporating 3D technologies in the design, manufacturing, and marketing processes contributes to reducing overproduction and waste, enabling companies to control their costs while pleasing consumers and generating great experiences.

3D technologies help improve demand forecasting

3D configurators offer consumers a chance for online product customization, enabling brands to assess market trends and demand without waiting for the sales data to get aggregated.

This offers brands a significantly higher degree of flexibility and agility, as they gain essential intelligence by tracking pre-sales metrics, analyzing shoppers’ online behaviors, preferences, the combinations they make when creating signature items, and the products they add to cart.

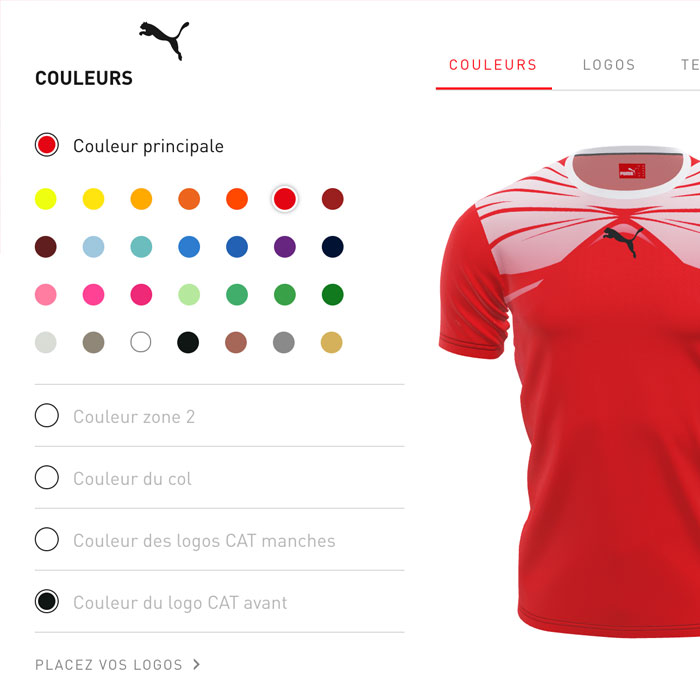

image credit: Hapticmedia 3D configurator for PUMA

The approach enables brands to understand what fabrics they should stock and what may be processed on demand to plan inventory and adapt to real-life shifts accurately.

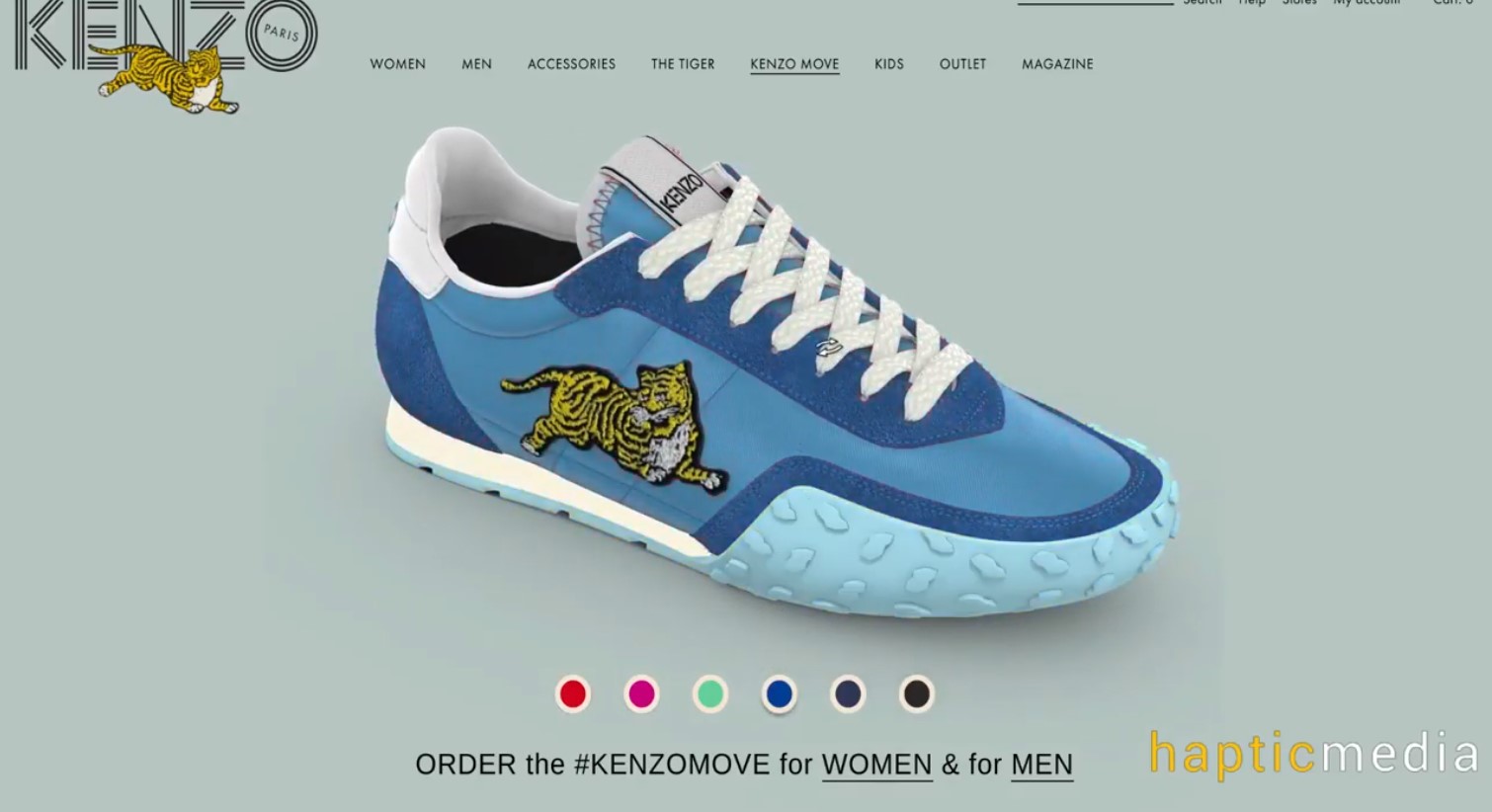

An innovator, Parisian fashion house Kenzo has been one of the first industry players to implement a 3D online product configurator that enables consumers to co-design their sneakers, choosing their fabrics and colors.

3D technologies shorten the production process

Using 3D models during production enables companies to accelerate time-to-market. By replacing actual samples with virtual equivalents, brands manage to save resources, cut down on expenses and reduce the time associated with testing designs & prototyping.

An accelerated time-to-market not only makes companies more competitive, but also increases their flexibility in relation with consumer demands, as they may respond faster to upcoming trends and shoppers’ requests.

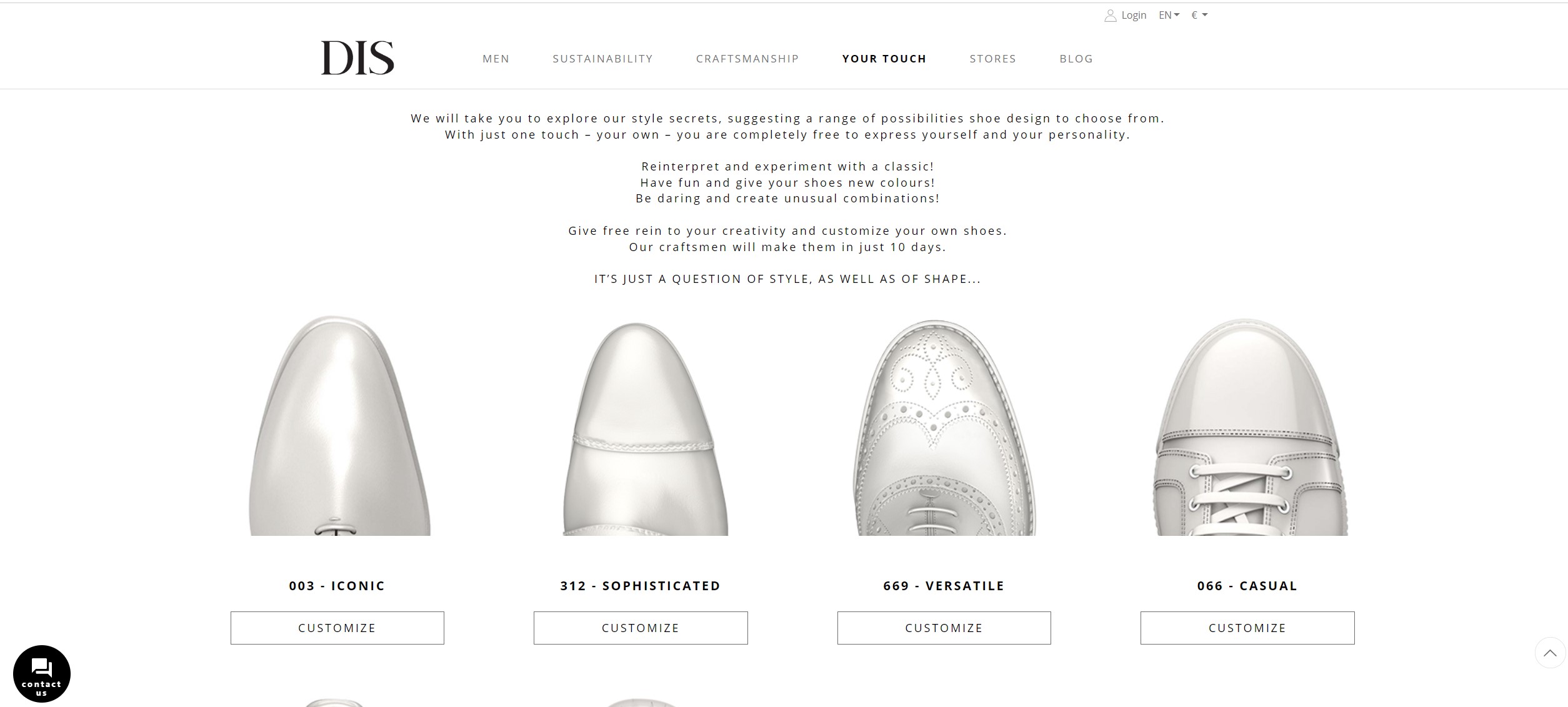

DIS – Design Italian Shoes uses 3D shoe models and an online 3D configurator to help consumers create their own leather footwear, by selecting from a wide range of colors and textures. At first, the delivery process lasted 20 days, but, as technology enhanced manufacturing, things were speeded up to 10 days. Now, the company is targeting a 5-day delivery on orders, and is bound to attain that without compromising on its signature quality, according to co-founder and creative director, Francesco Carpineti.

3D technologies encourage a no-stock approach

More and more fashion brands are discovering there may also be a no-stock approach to business that technology enables. By creating 3D models of their products, brands showcase items on their direct-to-consumer platforms, without producing them in real-life.

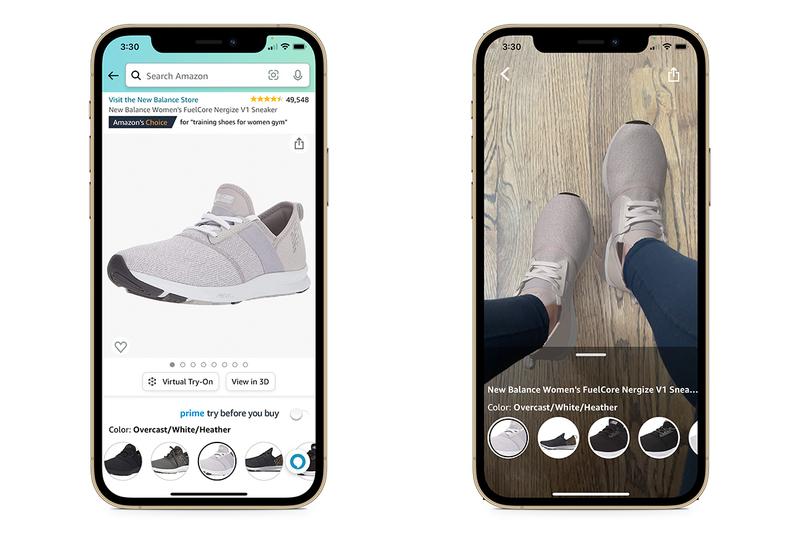

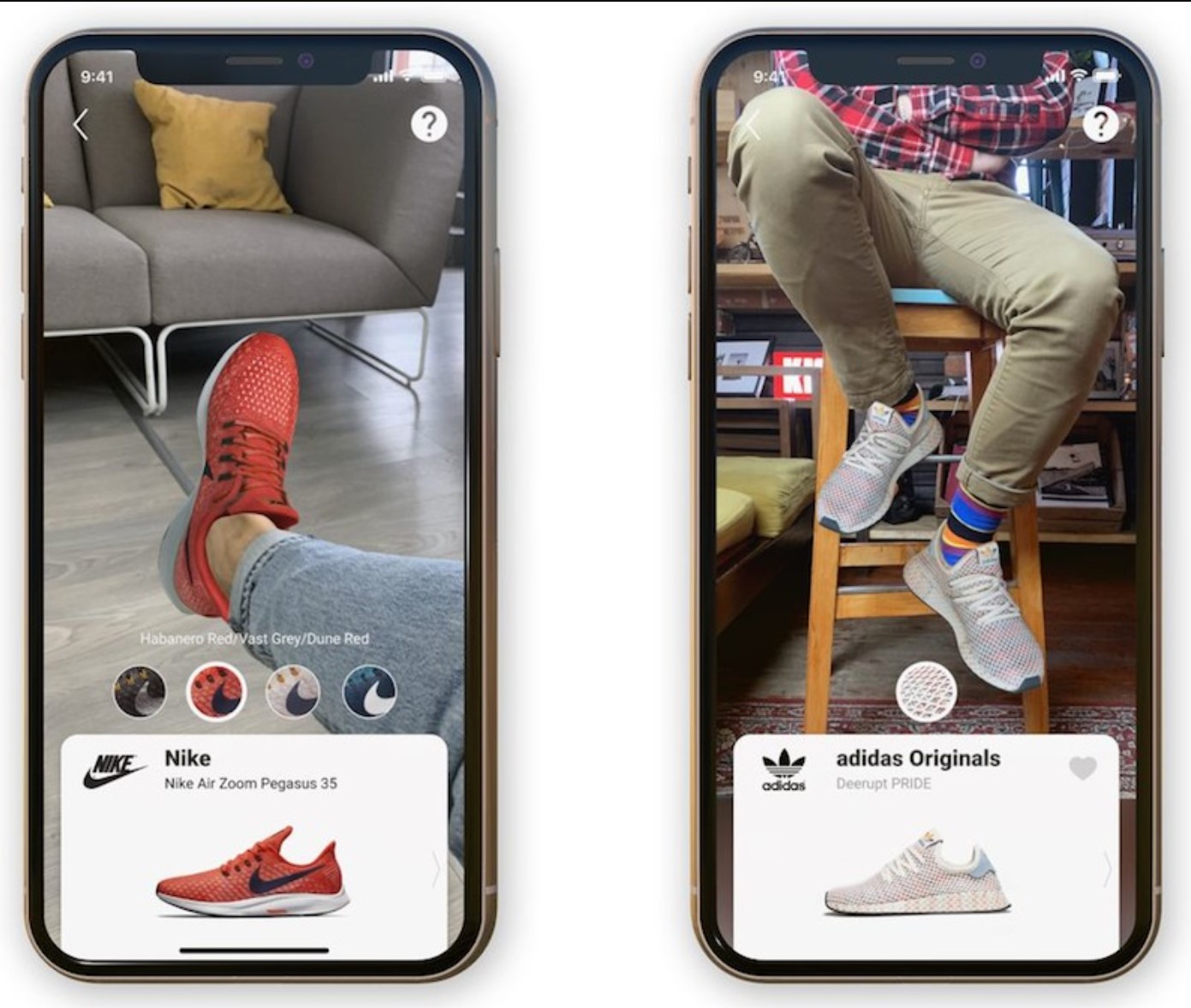

Some take it even one step further with virtual try-on, which means that shoppers may see how things look on them, before they are even produced.

This approach enables companies to produce only small batches of products that people may try to get a sense of how they fit, while most of the orders are only produced on-demand.

For generation Z-loved brand, Gucci, virtual try-on is an important part of its direct-to-consumer strategy, as the company enables shoppers to test everything, from make-up, to accessories, and shoes. Moreover, with the Gucci app AR features, users may also see how certain brand design items look in their spaces.

The tactic has become so successful that even Farfetch, which is not a manufacturer, is offering virtual try-on on Off-White shoes. Farfetch but also Amazon or even Nike.

3D technologies enable brands to offer made-to-order products

An excellent way to reduce overproduction, while increasing the desirability of your products is offering made-to-order items. If, back in the days, these unique combinations, which involved shoppers in the design process, were associated solely with exclusive, luxury brands, now mass customization is opening the door to a new brand-consumer relationship.

When using 3D technologies for online product configurators and mass customization, companies generate strategies that are win-win, for themselves and their clients.

Online product configurators help customers benefit from a unique, engaging experience and a rare fashion item that responds to their stylistical and aesthetical needs. This generates higher loyalty and word-of-mouth, while also reducing direct and indirect costs associated with overproduction.

Online product configurators are used by brands is a wide range of industries, from fashion to fine jewelry, and furniture.

Conclusions

Overproduction is one of the main issues and loss-generators in the fashion and retail world, but 3D technologies help brands find a way out. Our 3D online product configurator enables clients to implement zero-stock, mass customization strategies, without investing significant budgets in complicated tools. By using our Apviz SaaS solution, you get access to an intuitive, easy-to-use software product that connects by API with your ERP, CRM, DAM, and PIM.

Explore our feature and contact us to request one month of free access.